Sustainability, Animal Welfare and Business Efficiency; All Round Transformation

The client

The client is one of Norway's biggest food manufacturers, facilitating egg and meat production throughout Norway. It is farmer-owned, based on the belief that food should be produced keeping the next generation in mind, prioritising Norwegian resources and the local environment. The client supplies other food producers and restaurants, and is also a key supplier to many food outlets such as grocery stores, kiosks and petrol stations.

With more than 5,000 employees and over 17,000 owners, the client has a turnover of more than 20 billion Norwegian kroner. As part of a circular economy, any product unfit for human consumption is converted into new products including medicines, energy or animal food, among others.

The challenge

The scope of the project covered the improvement of animal welfare, optimisation and sustainability of farm operations, and improved efficiency for the farmers. Animal welfare is a key focus in the region and the client recognised this as a priority, so the brief included examining how the technology could be used to improve the animals' welfare. Customers in Norway now demand traceability in the food chain, including end-to-end transparency from the farmer to end customer. Each year, the industry reveals several violations of industry rules, regulations, and legislation pertaining to animal health and welfare. The client thus has a responsibility to uncover, advise and follow up with producers in cases where deviations from such rules occur.

A digital solution was therefore sought to monitor farm conditions in a way that complies with both internal and external regulations. This included measuring and reporting on health indicators, measuring pain, injuries or disease in the animals, and calculating their growth and weight to predict the optimal time for slaughter. Therefore, the collection of data from smart sensors to improve farmer efficiency and animal welfare was a prerequisite. Successful use of the data available from a working digital farm would therefore not only improve animal welfare, it would improve the efficiency of the farm; a win-win situation for livestock and farmers alike.

The solution

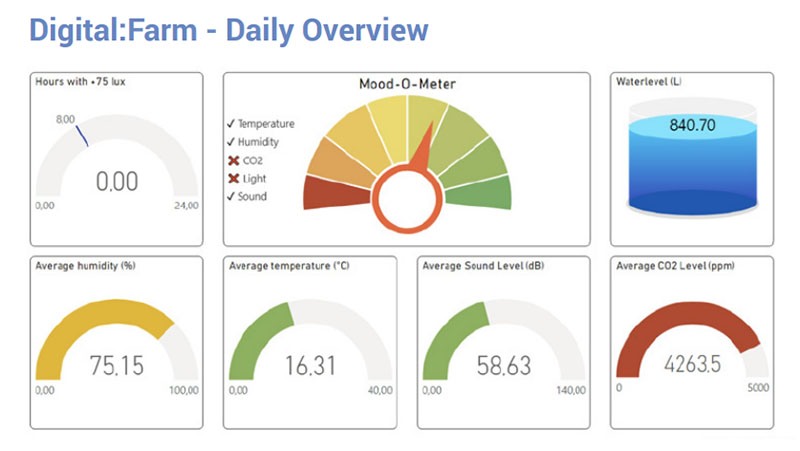

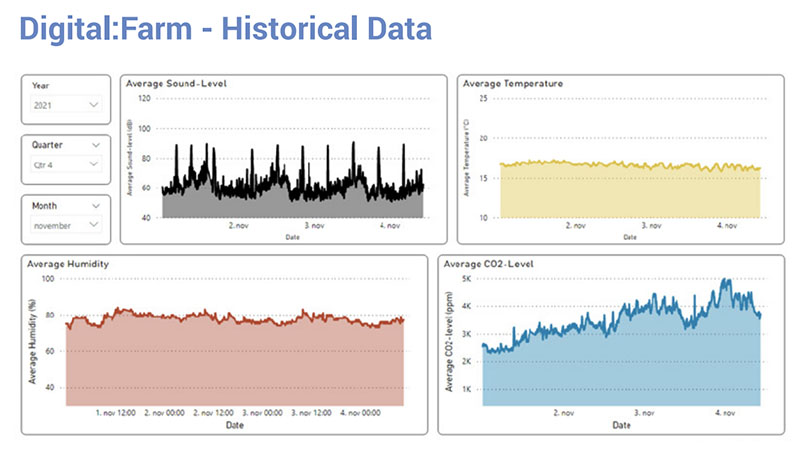

To tackle the challenges the client is faced with, NTT DATA suggested a range of measures, beginning with digitalising the farms through the introduction of sensors, cameras and microphones. An event warning system would be put in place that would trigger based on sound and picture information. Sensors would also be set up to ensure that basic welfare conditions are in place—including monitoring access to water and daylight—and that appropriate temperatures were maintained, as well as tracking sound levels, CO2 levels and humidity.

Artificial Intelligence and big data tech would be leveraged alongside connection to the Internet of Things, to parse the data coming in from the farms and not just detect but predict events that impact animal welfare. Further benefits would be gained through the use of computer imagery and AI algorithms to calculate and monitor the weight of animals, enabling accurate prediction of the optimal time for slaughter.

The result

NTT DATA's solution delivered across the full breadth of the project, even offering the opportunity to extend its scope and capabilities beyond the original brief.

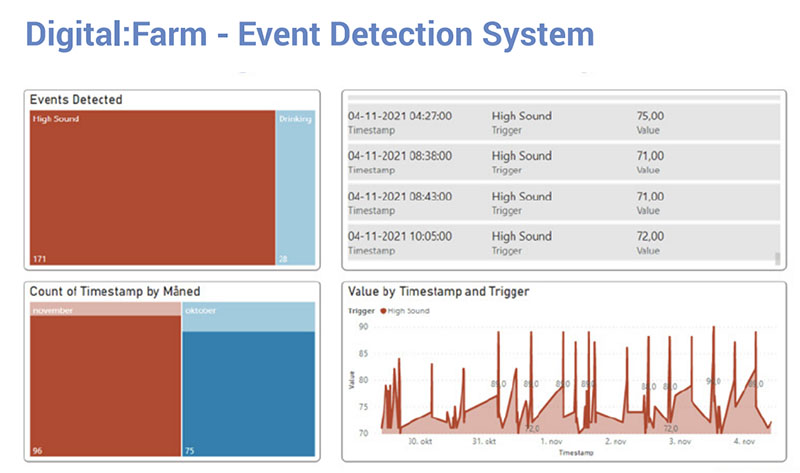

Improvements to animal welfare were made by introducing an early warning system to prevent disruptive behaviour, which in turn increases farm efficiency. Data audit trails have been put in place to prove compliance with animal welfare regulations. Data capture at both the individual animal level and across entire farms has provided the transparency and traceability that was a key requirement. A sound-based event detection system was incorporated to identify and record noise events, though more data and time is needed to analyse the correlation between health indicators and these events. Increased monitoring has also added to increased farm efficiency—farmers are now able to monitor farm and animal conditions from their mobile devices or other connected computers.

NTT DATA has created a skeleton model to calculate the weight and volume of individual pigs based on camera recognition. This data is used comparatively against standard growth curves, to both predict growth and estimate the optimum time for slaughter. It can also detect abnormalities and provide an alert so farmers can implement appropriate corrective measures.

The extended timeline and scope of the project gave NTT DATA the opportunity to introduce further measures. A new, more accurate event detection system was developed, detecting events based on sound peaks through a microphone linked directly to a camera, providing more accurate and correct detection. Furthermore, a new set of sensors was developed for the Proof-of-Concept stage, allowing for the comparison of information from different hardware vendors.

NTT DATA also took advantage of the extended period to capture and analyse more data to provide a more detailed and accurate solution for the client going forward. The data was used for training, fine-tuning developed models, and testing hypotheses on data models.

Why NTT DATA

There were a number of reasons that made NTT DATA the most capable and appropriate partner for this project. Firstly, NTT DATA's strong existing knowledge of the client's internal processes and operations meant they possessed a profound understanding of the challenges they faced. Already being a known and trusted partner, the client knew NTT DATA could be relied upon to deliver exactly the solutions that were needed.

A proven track record of their approach to digital R&D projects, as well as demonstrable success in technically similar projects delivered by NTT DATA's Innovation & Technology team, further strengthened their case.

NTT DATA also has extensive experience in connecting new core technologies with existing businesses and incorporating them into real-world frameworks, as well as a collaborative approach that includes stakeholders in the relevant parts of the process.

What's next

The next step is to plan and execute the extended scope test and develop the solution such that it is scalable to be deployed to additional farmers and farms. This will include the development of a simplified mobile user interface to make use of the system as simple as possible for end users, and the installation of so-called 'IoT in a box' infrastructure to enable localised data capture.

Data capture will also be extended to optimise development models, including the integration of growth data back to SAP to assist in the development of manufacturing and transportation planning. Ultimately, an end-to-end track and trace solution is proposed, providing blockchain-backed traceability for the food industry in the region.

Given the success of its implementation, NTT DATA also plans to introduce the 'digital farm' concept and solution to other existing relevant clients.

This article has been reprinted with permission from the website of "https://leap.nttdata.com/".

Related Links

You can see more LEAP case studies below.

https://leap.nttdata.com/case-studies/