The Product Carbon Footprint Conundrum

Today, we are in a race to reduce GHG emissions before climate change escalates to a point of no return from which recovery would be impossible. Consumers or buyers are increasingly choosing products with a lower carbon footprint. To accurately calculate product carbon footprints, emissions data must be collected from the entire value chain in a transparent and consistent manner. This article describes some of the challenges in doing so as well as some possible solutions.

Author 1:

Ravindra Sandaruwan Ranaweera, NTT DATA Group Corporation

Technical Lead, Research and Development Headquarters

Ravindra has over 10 years of experience in consulting, system integration, and R&D in distributed computing and data analytics technologies. Currently, he has been engaged in R&D activities focusing on emissions data exchange along the value chain.

Author 2:

Taichi Imura, NTT DATA Group Corporation

Deputy Manager, Green Innovation Office

Taichi has worked for NTT DATA for over 10 years and currently focuses on accelerating global collaboration on sustainability business to make the world more sustainable.

The pursuit of reducing GHG (Greenhouse Gas) emissions necessitates a constant drive for improvement and innovation throughout all industries. Companies are actively seeking ways to lessen the impact of their actions on the planet, as they face stricter regulations, investor demands, and changing customer preferences. In order to achieve sustainability, a multi-faceted approach that involves implementing changes within the organization, manufacturing processes, and business models is required.

The first step in any approach towards reducing emissions starts with correctly measuring the GHG emissions. With the release of GHG Protocol in 2001, organizational level emissions accounting has been accelerated, leading to the widespread adoption of reporting emissions by many organizations worldwide. On the other hand, in order to accelerate efforts towards net zero, it is essential to consider not only emissions at the organizational level, but also the emissions of individual products, or product carbon footprint (PCF). This is because PCF disclosure enables end-users to select products with low emissions, legislative agencies to impose regulations according to the emissions of each product, and buyers to select suppliers based on emissions which will encourage emission reduction.

Product Carbon Footprint Calculation

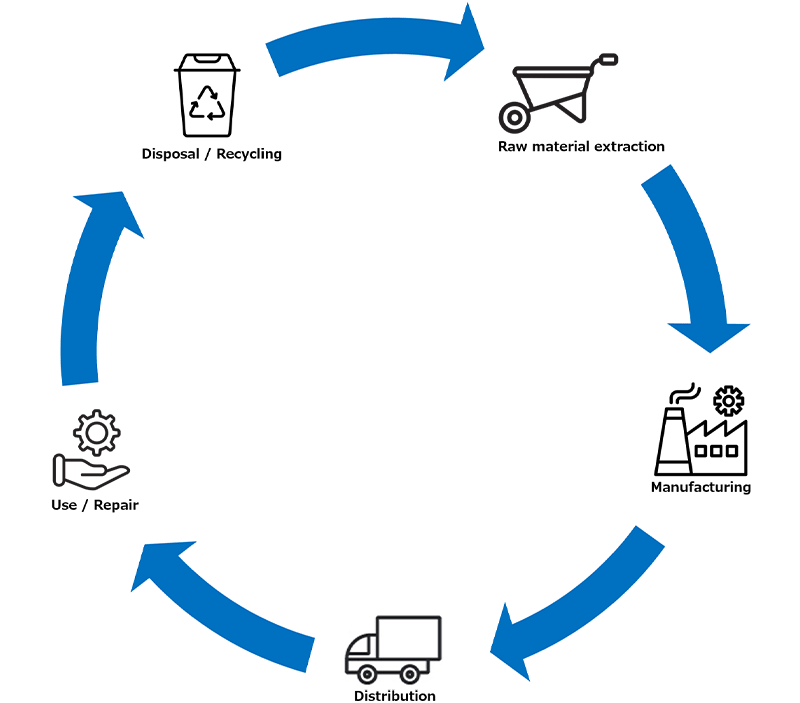

The Product Carbon Footprint stands as one of the most widely recognized approaches for assessing the environmental impact of a product. This is because a PCF communicates the GHG emissions that are produced or consumed during the life cycle – from raw material extraction to end of life – of a product or service.

Figure 1: The product life cycle stages.

A product's life cycle stage consists of various processes, with many value partners involved in each process, making it a complex task. Fortunately, there are basic standards and rules such as ISO 14067, PAS 2050, and the GHG Protocol Product Standard for PCF calculation.

Challenges in Calculating a PCF

Calculating a PCF by applying one of the above-mentioned standards is not as straight forward as it would seem. There lie numerous and diverse challenges when calculating an accurate and trusted PCF. In this article, major critical challenges and some possible solutions are presented.

1. Room for interpretation in current standards

When calculating a PCF, many companies refer to the basic standards mentioned above, except for some industries that have sector-specific guidelines or product category rules (PCR). These basic standards cover a wide variety of industries, leaving room for interpretation in their application when calculating PCFs. Since a PCF is calculated based on emission data input from different life cycle stage processes, any inconsistency in the data sources or the specific calculation methods will lead to PCF calculations that are inconsistent and thus not suitable to be used for comparison between different products.

A PCF should ideally be calculated based on the actual data, called primary data, which is collected by the partners involved in the life cycle of the product. Primary data allows us to calculate an accurate PCF and reflect emission reduction efforts in the PCFs provided to customers. However, existing basic standards do not provide practical guidance nor incentives to accelerate the adoption of collecting primary data. In situations where primary data is unavailable or inaccessible within the value chain, companies are left with the only option of using secondary data, such as industry averages or estimated data that are not collected directly by companies. Current standards do not provide trustworthy secondary data nor provide a framework for selecting high-quality secondary data. When a PCF is calculated based on secondary data, GHG emissions reduction efforts by suppliers are not reflected in the end product's carbon footprint as long as industry averages or generic data are not updated.

A possible solution to overcome the challenge of having various interpretations is to define one common standard across industries with strict rules that limit the ability to come to subjective conclusions. Such a standard would minimize the degree of openness to interpretation, resulting in comparable and consistent PCFs. In addition, the use of primary data should be strongly encouraged and guidance on how to use secondary data would be a plus. The World Business Council for Sustainable Development (WBCSD) has taken the lead in developing such a standard for calculating and exchanging primary data-based PCFs along the value chain under PACT (Partnership for Carbon Transparency). The Pathfinder Framework not only leverages and aligns with existing standards, it also works as a supplement to the existing methods and standards. The framework was developed to be used by different industries, providing a solid foundation that can be expanded upon to address specific requirements within each sector. It also provides safeguards for using secondary data when primary data is not available, such as primary data share, as well as metrics such as data quality that represents the quality of the emissions data being shared. In addition to these methodologies, PACT also provides general data exchange guidelines and technical specifications to exchange data across the value chain.

Even though the Pathfinder Framework is the right step towards solving some of the most critical issues in PCF calculation, room for improvement exists, including improving scalability for companies with a large number of products, having a solid emissions data verification scheme, requiring interpretation for certain aspects of specific industries, etc.

2. Lack of a mechanism for securely sharing data

For an accurate calculation of a PCF, a company must map the total value chain associated with the product and pinpoint all sources of emissions. Today's value chains are often complex, involving multiple tiers of suppliers worldwide. In most cases, exchanging data between the parties involved is difficult due to deep hierarchies, complex value chain structures, and different sizes of suppliers. Another major obstacle that hinders data sharing is the risk of sharing confidential, trade secret data. It is suspected that granular emission data enables other companies to reverse engineer products, providing valuable insights into detailed production processes such as component structure, materials, and supplier information, which are considered to have competitive significance.

Recently, several initiatives aimed at securely sharing emissions data across the value chain have been created. The ESTAINIUM Association for cross-industry and Catena-X for the automotive industry are some of the more well-known initiatives. The digital infrastructure provided by these initiatives allow companies to securely share emissions data along the value chain.

The ESTAINIUM association is one of the front running initiatives promoting product-related decarbonization. ESTAINIUM provides a common platform to discuss such topics with other like-minded entities from various industries.

ESTAINIUM Association

The ESTAINIUM association is an open and independent association that represents diverse disciplines that focuses on calculating, exchanging, reducing, and offsetting emissions along the value chain. It was established as a platform to enable emissions data to be shared along the value chain in a standardized and secure manner. PCF data is exchanged along the value chain using a decentralized approach, while also enabling them to be verifiable by the receiver. The ESTAINIUM association adopts a comprehensive approach to effectively reduce emissions from the industrial value chain.

![Figure 2: Holistic Emission-to-Sink approach to decarbonize the industrial value chain [1].](/global/en/-/media/nttdataglobal/1_images/insights/focus/the-product-carbon-footprint-conundrum/img02.jpg?h=437&iar=0&w=800&rev=8bfdaf86622a47d7a5cb92122402a23e)

Figure 2: Holistic Emission-to-Sink approach to decarbonize the industrial value chain (1).

NTT DATA along with other ESTAINIUM members focus on solving the challenges of establishing a path from carbon emission to carbon sink along multistage, complex value chains, including the issues related to PCF calculation. Some of the topics related to PCF include alignment on PCF calculation methodologies and data models, high data quality, streamlined assurance criteria as well as secure and trustworthy emissions data sharing infrastructure and technology. For carbon offsetting, developing guidelines to integrate high quality carbon removal projects into carbon accounting mechanisms are being considered.

Three working groups within the ESTAINIUM association focus on these topics: WG 1: technology and infrastructure, WG 2: standards and norms compatibility, WG 3: carbon capture, use, storage and compensation. A snapshot of the three working groups'activities and results have been published as a white paper for public reference (2). ESTAINIUM plans to confirm the feasibility of the results obtained through several pilot projects, some of which have already started.

As a company striving to create a sustainable future, NTT DATA contributes to these working groups with its extensive know-how and experiences gained in the IT field. Some of these contributions include laying the groundwork for pilot studies about PCF management application interoperability, participating in the development of the ESTAINIUM knowledge hub, sharing knowledge gained while developing our own carbon sink solution (CO2Sink (3)) for the ESTAINIUM Carbon Sink Matrix (4), and pursuing the possibility of using CO2Sink in pilot projects.

Conclusions

Reducing GHG emissions is one of the most urgent challenges we are facing today. Creating a market where products with less emissions are selected, thus creating a competitive environment between companies, is one approach to reduce overall emissions. In the past, there were efforts to spread PCF labeling for general consumers, but these initiatives failed to make an impact on the market. This was because the standards were too strict, the related costs were too high, and the benefits were too few. However, recent initiatives have learned from past failures and now focus on providing value to both consumers and industries by creating clear and reasonable standards. In order to create such a future, consistent, accurate emissions data must be shared along the entire value chain, which is a rare practice in today's world. Initiatives such as PACT, ESTAINIUM, and Catena-X have started taking action to solve the PCF conundrum. NTT DATA will also continue to contribute to these initiatives in our pursuit of obtaining a more sustainable future.